Formulators now have the ability to formulate paints and coatings in one digital platform. What benefits does this tool bring to the R&D processes?

There’s no reason for R&D teams still functioning in the same manner that has been in place for decades.

Because today we know how to digitize individual chemical/material, you can streamline the research and development process, save money and materials, and use time much more efficiently.

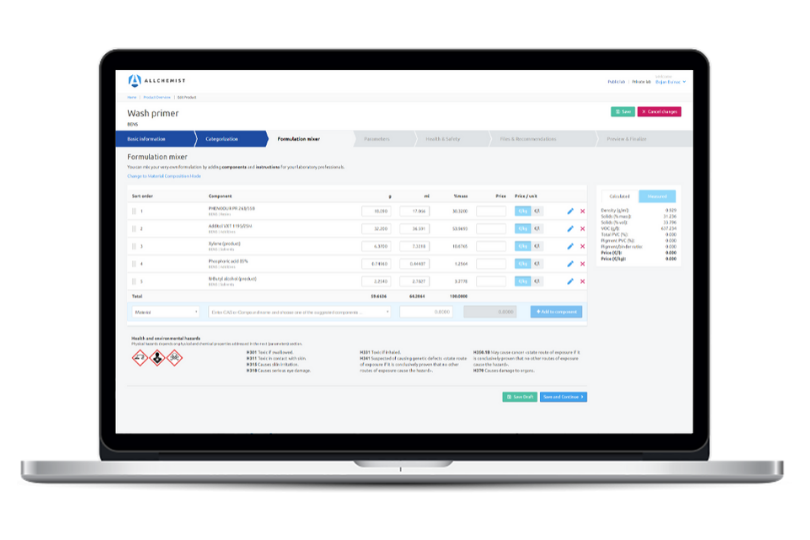

Allchemist helps you to cover the whole development process – from an idea through mixing raw materials, creating a product or make a fast reformulation as well as get the product to the global market in record time.

Download the Free White Paper

Digital Future of Coatings Development is Here

Learn how can you save up to 48% of the throughput time for conceiving and launching an entirely new product.

1. No more PDF docs

The traditional method of data acquisition used to involve requesting data on raw materials from chemical suppliers, receiving it in PDF form and inputting the data into in-house software.

In Allchemist formulators have the ability to not only search materials by more than 1000 properties and 120 parameters, but actually “play” with endless possibilities. For example, with the parametric search, it is easy to find an additive with a refractive index around 1.40, of viscosity around 30 mPas and with iodine color number equal to 1 in just seconds.

You can use chemicals/materials from the public lab (pre-filled with various materials) or create your own private lab of materials/chemicals you are using.

2. Virtual pre-lab experimentation

By putting different materials in a new or existing formulation, the formulator can immediately observe a change of formulation hazards and calculations like density, solids, VOC, pigment/binder ratio and so on. Formulators can also add prices they got from suppliers and get a better idea of product production cost.

Allchemist is developed for almost everyone working in the paint and coatings industry: having entire product portfolio in a digital form, suppliers and distributors can stay connected with their clients (formulators) in the same, highly secure digital environment; Management can track R&D teams all over the country or internationally – that avoids working on the same project in different departments.

3. Save non-added value time

This software revolution can offer the same optimizing to the pre-lab experimentation phase, eliminating costly and time-consuming lab tests that can be shown to be unnecessary through virtual experimentation via modeling software. The result is fewer lab tests, thereby getting to end results— new products—more quickly.

Download the Free White Paper

Digital Future of Coatings Development is Here

Learn how can you save up to 48% of the throughput time for conceiving and launching an entirely new product.